The difference between cold and hot rolling

Release Time:

Aug 25,2024

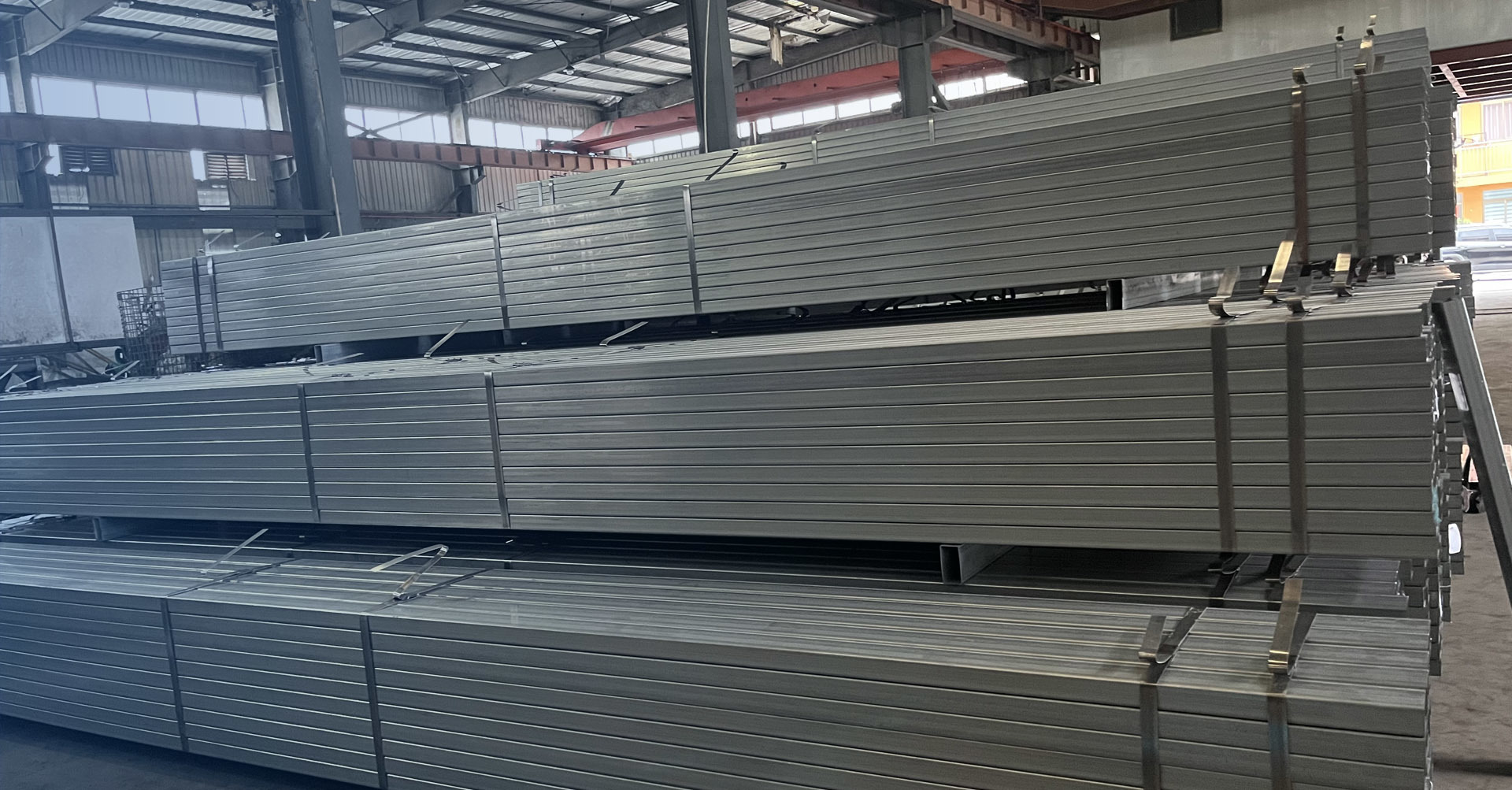

Cold rolling and hot rolling are two methods used in metal processing to shape and form metal sheets or bars.

Cold rolling and hot rolling are two methods used in metal processing to shape and form metal sheets or bars. The main difference between the two processes lies in the temperature at which they are performed.

Hot rolling involves heating the metal above its recrystallization temperature, making it easier to deform and shape. This process results in a more malleable and ductile metal, allowing for a wider range of shapes and sizes to be produced.

On the other hand, cold rolling is done at room temperature or slightly above it. This process produces a harder and stronger metal with a smoother surface finish. Cold rolling is often used to produce thinner and more precise metal sheets or bars.

In summary, hot rolling is done at high temperatures to create malleable metal with a wider range of shapes, while cold rolling is done at room temperature to produce harder and more precise metal products.

Keywords:

More information

Our company website officially launched operation

We are excited to announce that our company website is now live and officially launched!

Stainless steel pipe selection precautions

When selecting stainless steel pipes, there are several important precautions to consider.

The difference between cold and hot rolling

Cold rolling and hot rolling are two methods used in metal processing to shape and form metal sheets or bars.